Fabrikatör automates the replenishment process based on real-time inventory data. By placing orders with suppliers when the stock hits a predefined reorder point, you reduce manual effort and ensure stock is replenished before it reaches critically low levels. This automation helps you maintain optimal inventory levels effortlessly, preventing stockouts and excess inventory. A better understanding of ideal inventory levels leads to increased lead times and accuracy when placing orders with suppliers.

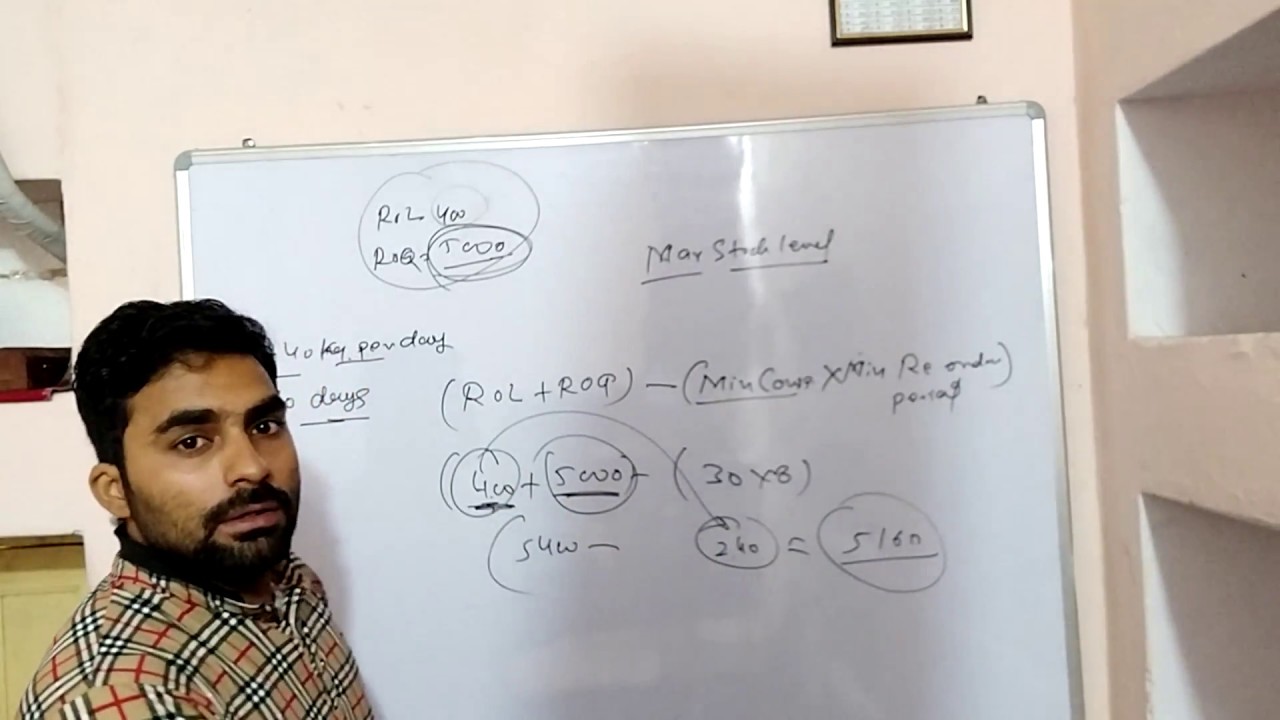

Example of how to calculate optimal inventory level

Weeks of supply (WOS) is how long it’ll take to sell through your on-hand inventory based on current demand trends. And the ideal time to replenish is when WOS is roughly 2 weeks longer than your order lead times. As such, your maximum inventory levels should be calculated before you place a purchase order (PO) to prevent over-ordering. For instance, when your inventory levels are low, you won’t have enough inventory to fulfill all the demand that comes your way. During that stockout event, you miss out on sales and revenue if you don’t sell those products on backorder.

Safety Stock + Reorder Point + Economic Quantity

This way, you always have a wildly more accurate forecast to determine when, what, and how much stock to order. Maximum inventory levels are the ceiling amount of stock you should have on hand for each SKU. Anything more above that threshold is considered excess inventory and introduces unnecessary inventory risks (like higher costs and waste). You know that your average daily demand is five mugs, the standard deviation of your demand is two mugs, the average lead time is one day, and the desired level of safety is two. The frequency of placing orders and the size of order batches can also impact min and max stock levels.

Which of these is most important for your financial advisor to have?

By implementing these strategies, businesses can effectively manage min and max stock levels, optimize inventory costs, and enhance supply chain efficiency. The maximum stock level represents the upper limit of inventory that a business should maintain. It acts as a safeguard against overstocking, which can lead to excessive storage costs, inventory shrinkage, and product obsolescence. You would have to constantly recalculate your minimum stock levels in order to be truly prepared for eventualities such as supply bottlenecks or increased order volumes. By optimizing inventory levels and using inventory management software to streamline the entire process, companies can gain more control over their operations and maximize their potential earnings. Thanks to all the collected data and reports, you can be sure you’re maintaining optimal inventory levels to bring in the most profit.

Would you prefer to work with a financial professional remotely or in-person?

However, some businesses use average usage/demand and average lead time figures for computing the reorder level of their stock. In some scenarios, it may be unlikely that the reorder level could be estimated accurately. This is because the demand and the lead time of the goods could differ than the usual trends and in that case the business may run out of stock. There are a few different methods that can be used to calculate minimum inventory levels, all of which we’ll review in this post. Gone are the days of relying on dusty spreadsheets for inventory management.

- Every business has to maintain a certain level of raw materials or finished goods in its store.

- One of the best ways to ensure you never run out of a product is to get control of your minimum stock levels.

- For this reason, using tools such as optimal stock levels eliminates errors and overcosts, guaranteeing enough inventory to satisfy the demand for each SKU without incurring unnecessary costs.

- As a result, employees and storage locations are not overloaded with unnecessary products or are unable to increase sales due to lack of inventory.

- These predetermined thresholds can be fixed quantities for each item or dynamically adjusted based on sales trends using real-time sales data from a perpetual inventory system.

- Its integration with supplier databases enhances communication, ensuring swift replenishment and centralized control over multiple inventory locations.

Where Q is the optimal order quantity, D is the annual demand for raw material, K is the cost of each order, and G is the cost of storing a product for a specific amount of time. As a result, thanks to the EOQ formula, the warehouse manager will know when an order should be placed. Maintain a minimum stock level if materials serve multiple centers and come from diverse suppliers.

This can lead to not achieving the desired profits during a high season when you plan to maximize your sales. Another consideration when it comes to types of inventory is specialized storage requirements. For example, large or temperature-sensitive products may not be feasible to carry in greater quantities, even if they’re popular products. In this case, it’s advisable to keep a lower inventory level and negotiate smaller but more frequent supplier deliveries.

These predetermined thresholds can be fixed quantities for each item or dynamically adjusted based on sales trends using real-time sales data from a perpetual inventory system. The minimum level of inventory is a kind of a precautionary level of inventory which indicates that the delivery of raw materials or merchandise may take more than the normal lead time. Lead time is the expected time taken by the supplier to deliver goods at the warehouse or at the point of consumption.

Thus, as average sales increase, so do minimum and maximum reorder points. Similarly, when delivery times are longer, the minimum level is more important to cope with unforeseen events. The proper value of products in stock management varies according to the characteristics of the companies. Demand forecasting relies on historical sales data and real-time demand trends to predict how many units a brand will need to meet customer demand.

Optimal levels ensure that you never invest too much capital upfront for unnecessary inventory. And you get a bigger return because the inventory isn’t accumulating unnecessary carrying costs that deplete gearing ratios: definition types of ratios and how to calculate margins. Optimal inventory levels ensure you never have too much or too little inventory at any given time. And when a DTC brand maintains that kind of inventory control, they benefit in a myriad of ways.